3 2 Milling

A number of cam software suppliers have developed special utilities to create tool paths.

3 2 milling. Introduction to 3 2 milling. The process also known as 5 axis positional machining relies on the fourth and fifth axes to orient the cutting tool in a fixed position rather than manipulate it continuously during the machining process. One way to think about 3 2 machining is to visualize how selected. Simplify 3 2 and 5 axis machining with dwo tcpc haas automation tip of the day duration.

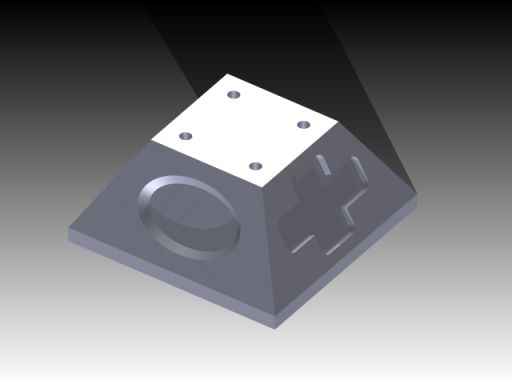

Cam software for 3 2 machining. In this final lesson we will take our first look into the world of 5 axis machining by programming a 5 axis positional or 3 2 milling part. While this part may seem more complex than parts in previous lessons we will continue to follow the same workflow to help guide us through the programming of this part. Some are more efficiently produced using 3 2 machining where the machine executes a 3 axis milling program with the cutting tool locked in a tilted position using its two rotational axes.